What is ESD Flooring?

ESD flooring (Electrostatic Discharge) protects electronic components from damage caused by static electricity that builds up when walking.

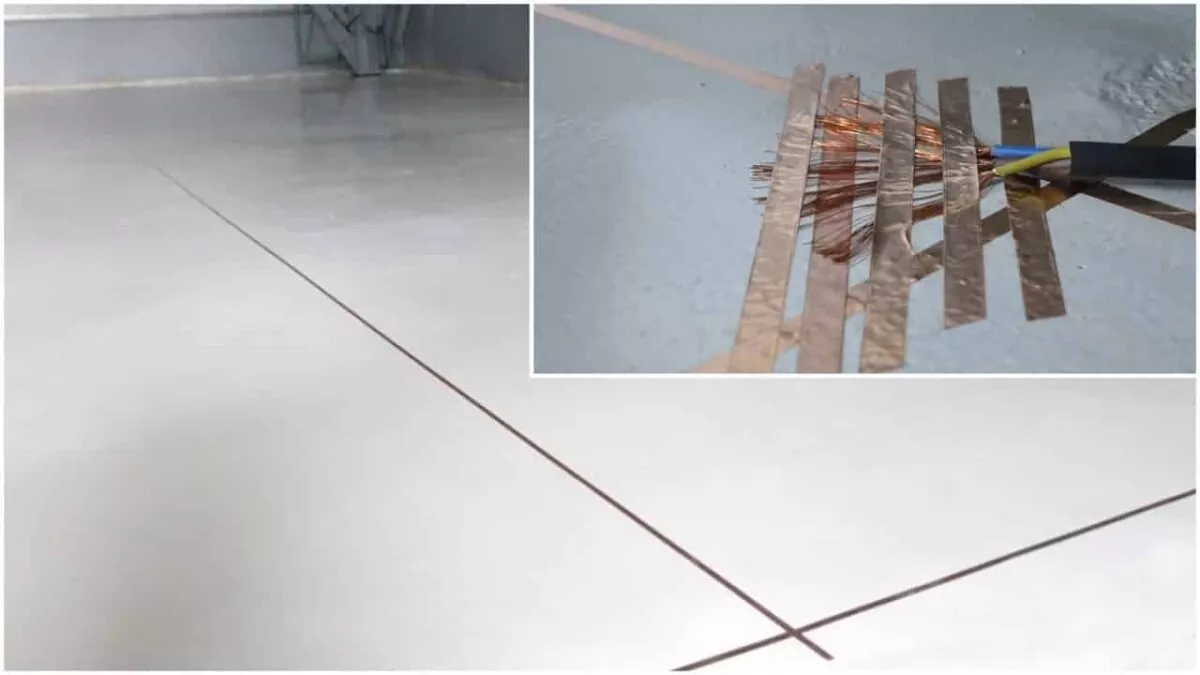

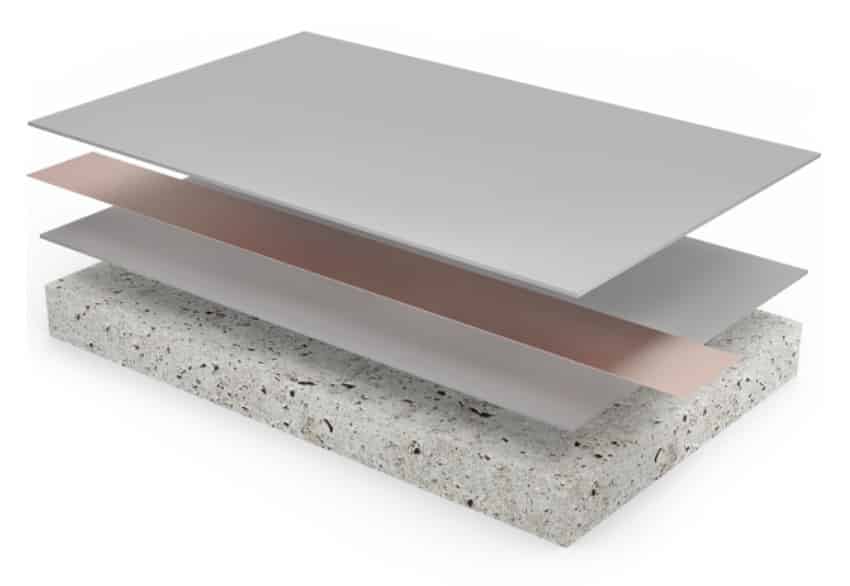

Moreover, conductive elements such as carbon, graphite, or metal-coated particles are distributed throughout the flooring material. In fact, coating imparts electrical conductivity to the floor and creates an electrical path from the tread to the floor.

Without a doubt, when a person walks on a standard epoxy floor, it is effortless to build up static electricity from friction as the epoxy acts as an insulating material. However, where there is static electricity, there is electrostatic discharge. This issue can create chaos in specific industries.

Also known as static dissipative floors (1 Mohm to 1000 Mohm) or conductive floors (0.025 Mohm to 1 Mohm), ESD flooring provides excellent static control. Above all, it prevents a person’s static electricity from reaching sensitive equipment.

Advantages of ESD flooring

ESD flooring uses conductive elements in the flooring material, which decreases the resistance of the flooring. Because electricity takes the path of least resistance, ESD coating forces static electricity (which would otherwise build up) down through the flooring.

Obviously, cast-in-place ESD polymer floors are more effective and complete than other types of anti-static flooring such as mats or tiles. In addition, conductive elements in a cast-in-place polymer flooring help bridge the path from the floor surface to the system’s ground layer.

Performance highlights include:

- Increase personnel protection from injury or death from electrical shock or explosion.

- ESD coatings are best to protect people working in clean rooms.

- They protect sensitive electronic components from harmful static electricity (in computer and electronics manufacturing).

- Performs better than tiles, which can delaminate under heavy use

- Save money on replacing or repairing electronic equipment from failure or damage by static electricity

- Creates a 100% effective electrostatic controlled environment, complete with ESD shoes

Where use ESD flooring

Controlling static electricity is critical for many industries. For example, antistatic floor coverings can protect sensitive electronic devices in computer and electronics manufacturing.

Even 250 volts can damage sensitive electronic components, circuit boards, and microchips. You may feel 2,500 volts of static electricity. Therefore, many manufacturing facilities that produce pills, sugar, grain, or ammunition – implement ESD flooring to protect workers. At worst, static electricity from explosions can cause fatalities.

Airborne grain and sugar particles and fine powders used in the pharmaceutical industry to manufacture pills can become flammable. A static electricity arc can ignite in these environments and cause large explosions.

Recommended industries to use:

- Electronics – assembly areas, manufacturing, inspection labs, cleanrooms, distribution centers;

- Aerospace – clean rooms, assembly areas, repair shops

- Pharmaceutical – R&D areas, clean rooms

- Auto Manufacture – chip manufacturing, electronic production areas,

- General – solvent storage areas, assembly areas

best eSD Systems to use

Our line of ESD flooring uses conductive materials in combination with the best in the industry epoxy coating systems. Some anti-static systems use carbon-filled primers, while others use conductive pigments.

In addition to the conductive advantages, all of our ESD floorings retain the same outstanding properties as our other floorings: they are chemical resistant, abrasion-resistant, and easy to clean.

Our DUOMIT team of area managers, architecture, and engineering representatives will help you choose the best ESD product for your environment with the look you want.

Recommended materials:

- Sikafloor ESD Control – for heavy industrial environments, electronics manufacturing

- Dur-A-Gard ESD – manufacturing areas, pharmaceutical, aerospace, all other ESD solutions