MOISTURE PROTECTION

Best Way to Protect Your Concrete from Moisture Damage

Why need a Moisture mitigation system? To begin with, the cost of moisture-related flooring issues or the absence of a vapor barrier should be disincentive enough to send any flooring professional searching for solutions. It’s expected that approximately $1 billion is spent every year on floor-related failures due to moisture in the subfloor.

Prevention from Moisture-Related Flooring Issues

Firstly, the most effective preventative measure for moisture-connected flooring issues is time. Time for the concrete slab to dry sufficiently. Time is needed to admit moisture levels to reach specified tolerances of used materials.

Moreover, a typical indication of high moisture levels obstructing installed coatings may include:

blistering and bubbles

delamination or coating failure

discoloration and crazing

efflorescence and warping

How to block Moisture in concrete

Moisture Control System – is flooring insurance as it reduces the risks of moisture-related issues when vapor barrier application’s cost upfront can compensate for potential disasters during epoxy coatings application.

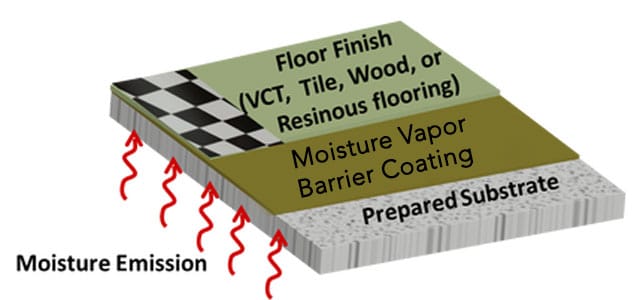

The purpose of any moisture mitigation system is to eliminate water vapor movement into the coating system. This includes water vapor from groundwater and moisture vapor from an insufficiently dry concrete slab, such as off-gassing.

Regardless of the source, high moisture will migrate from high concentration areas to low concentration areas until it reaches a state of equilibrium. Interfering that natural process is the key to preventing moisture issues.

Applied Membranes as Vapor barriers in your moisture control system

This includes epoxy or polyurethane primers. Furthermore, Moisture control membranes are applied on a concrete slab to reduce the permeability between concrete and final coating applications. Cementitious layers or acrylic latex resins create this non-permeable shield layer to prevent moisture migration.

In this case, the coating manufacturer specifies vapor barrier products to ensure proper installation and performance. Also, Ardex and Schonox deliver one and two-coat moisture control systems to address problematic moisture vapor emissions in concrete.

Moisture Testing

Lastly, measuring accurate moisture Relative Humidity (RH) levels in the concrete slab is imperative before the coating application project.

Above all, moisture testing provides the best indicator of the slab’s RH level for concrete slabs, showing when the subfloor is ready for coating installation. It can also help determine the project’s proper coating product selection.

Thus, everything from the concrete mix to the project environment contributes to the RH levels in the concrete slab, and only RH testing can provide reliable measures.