Cold Storage Panels – Authorized Installer New York

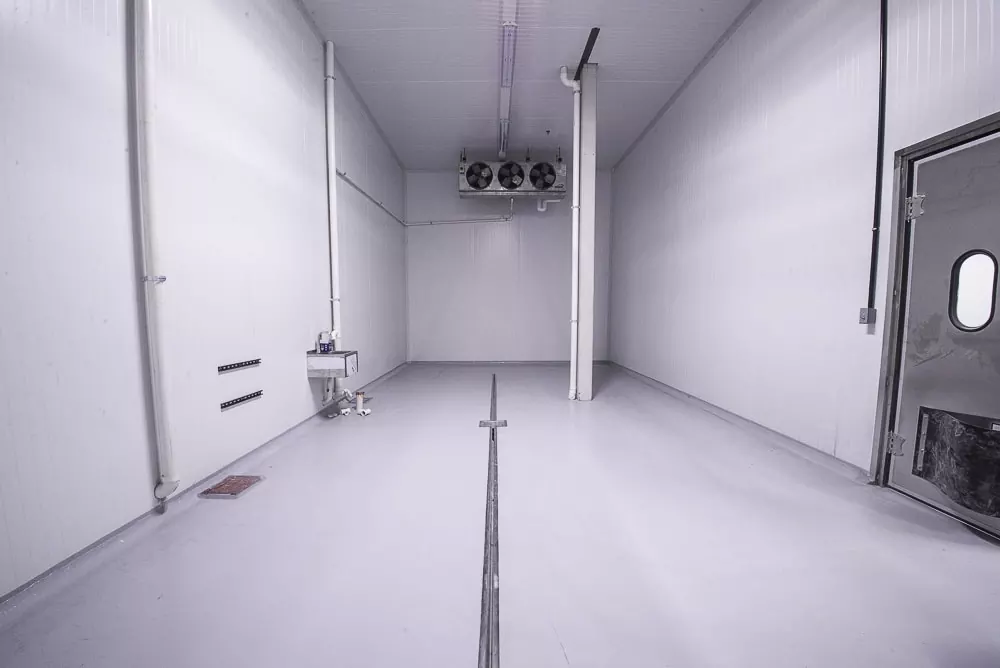

Walk-in cold-rooms supply chain solutions include the insulated cold storage panel systems for walls and roofs and Insulated Doors. The diverse product line offers a highly efficient perimeter for temperature extremes, from stainless steel blast freezers to pharmaceutical stability rooms.

Firstly, insulated Metal Panels function as walls, ceilings, and roofs for the cooler, freezer, and food processing buildings, in new and retrofit construction. Secondly, panels are ideal for dry goods warehouses and other environmentally controlled buildings. Where temperature control and thermal insulation values remain critical.

DUOMIT install insulated metal wall panels that applying to atmospheric controlled environments. In a case where high-cost finished product protection and hygienic control are of extreme importance. Moreover, roofing and wall panels are in use to fit any thermally controlled cold room’s needs.

Insulation Panels Features & Benefits

Superior Insulation Value across the entire wall and roof area secure with panels. Actually, they increase in “R” value and increase energy efficiency and thermal performance. This unique feature provides a cost-effective building design and increases the insulating qualities of the roof panels.

One-Step Installation process assures rapid completion of the storage facility. Factory fabricated composite panels with foam core are attached directly to the supporting structure.

On the other hand, reducing multiple steps to build the cold storage walls and roof will shorten construction time. Also, faster industrial building completion means reduced construction and interim financing costs.

Impermeable Exterior and Interior Faces ensure the highest insulating values are maintained for the life of the building. Exterior walls are manufactured with impermeable faces.

Although the installation of the insulation is completely encapsulating by metal trim that creates an impermeable membrane on all sides of the sandwich panel. As a result, the aged “R” values are comparable to the initial “R” values many years after the building’s original completion.

Class 1 Polyurethane Foam meets the requirements of the major model building codes for cold storage construction. Unlike a roof system with expanded polystyrene cores, they will not produce a self-propagating fire. Local building codes may require automatic fire suppression systems for most installations.

Panels are Lightweight, yet very strong and durable attributing to reduced costs for erection and structural support.

Finally, we provide precise technical support and customer service of Cold Storage Panels. Superior wall applications to our clients in New York City. Further, Kingspan is our Cold room panels supplier. We also cooperate with other brands.