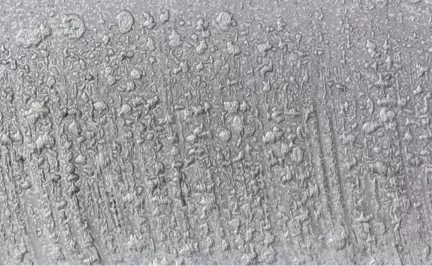

Why Concrete Slab is Blistering?

Concrete men hold various opinions about what causes fresh concrete to blisters occasionally, especially during the cooler seasons.

The reason blistering occurs on the concrete is when air gets trapped above the top surface. Air can not break out of the seal created during finish troweling or caused by a rapidly setting concrete surface. As a result, the air collects in spots under this airtight surface seal and produces blisters.

Why concrete blistering?

Many factors may be responsible:

- Winds were blowing over the concrete surface and reducing surface moisture.

- A subgrade that’s cooler than the concrete.

- A viscous mixture with redundant fines that seal the surface quickly.

- Lean mixtures have to be trowel good enough to produce desired finishes.

- Too early finished concrete, by hand or machine.

- Improper use of tools.

What happens in concrete?

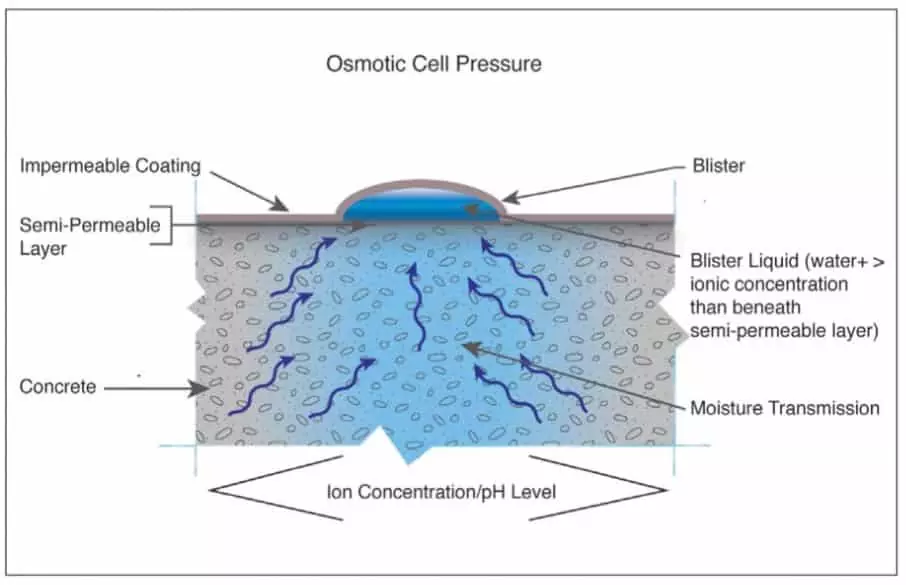

Whenever it is windy during concrete finishing operations, the surface dries rapidly, and surface friction increases. This is a crusting process. Because of the surface stiffness, the concrete looks as if it were ready for finishing, but underneath it’s still spongy.

Then, when the finisher begins to work the concrete, the air is forced to the surface, becomes trapped under the already-sealed crust, and creates blisters.

Blistering may not show up on the first troweling pass. However, as soon as the pitch of the trowels increases for the second or third pass and surface density and friction increase, the blisters appear.

Entrapped air is forced ahead of the trowel blades under the surface skin until enough is concentrated to form blisters. Flat troweling at this point can minimize the problem. On windy days the finisher should vary operations somewhat. Windbreaks and sunshades are a great help, but specialists should keep using a vibrating screed and bull float to a minimum.

A wood bull float opens the surface and gives the best results when crusting occurs. Tried and proven cures When the water sheen has left the top layer, and the concrete has set sufficiently to bear a man’s weight with maximum indentation of 1/2 inch, the finisher can use a magnesium hand float for the first hand-floating.

Factors Of Blister Formation

If you use machines, the lightest ones should be a preference. However, when extreme moisture deficiency is causing heavy crusting, the slab may have to be sprayed with a fog spray or covered with damp burlap or polyethylene.

The finisher may hand trowel after hand-floating. Suppose the finisher can determine that the subgrade temperature is lower than the concrete temperature. In that case, the finisher should heat the subgrade before placing the concrete to avoid a premature surface set. Again, proper proportions are necessary to prevent sticky or lean mixtures or excessive fines in the concrete.

Use a minimum of 5 1/2 bags of cement per cubic yard to get a workable, adequate mix with a finishable paste. Over-sanded mixes or those with small maximum size coarse aggregates may require at least six bags of cement. Some water-reducing admixtures will increase the stickiness of the mixture and cause surface crusting.

Most common mistakes

If the concrete is sticky and lacks workability and finish ability, check the water reducer. This can be a significant contributing factor. In addition, improper use of tools can cause before sealing of the surface. These are some common misuses:

- Too many passes of a vibrating screed on concretes with slumps from 1 to 2 1/2 inches.

- Using a vibrating screed on concretes with slumps over 2 1/2 inches, producing excessive surface fines.

- Excessive use of jitterbugs, especially on high-slump concretes.

- Excessive use or pitch of wood or magnesium bull floats. Smoothening of a surface by the magnesium bull float creates bull float pitch critical. Unfortunately, most finishers overuse the magnesium float, resulting in concentrated surface fines and a weakened plane below the surface.

- Machine floating with blades not flat to the surface. The clip-on float blades usually are better than the combination-type blades that tend to seal the surface.

How to Avoid blisters? Finishing guidelines.

Follow some simple guidelines when finishing concrete. Air entrainment reduces bleeding and increases surface friction.

The Concrete Slab Blistering— Cures and Causes means that appropriate timing of the finishing procedures is necessary. Also, the use of a magnesium hand float is a must. Float the concrete twice, if time permits. If concrete sets rapidly, float at least once and lap each machine pass about one-half the device’s width.

While troweling with a machine, remove the float blades and make the first pass with the trowel blades flat to the concrete slab. Keep the trowel blades as balanced as possible for the following keys, and allow adequate time between passes.

If the machine leaves any imperfections, follow the final pass with a hand trowel to eliminate them. If a fog spray is used for the last machine pass because of high surface friction, keep the fog to a minimum, with nozzle volume not exceeding 1/2 gallon per minute.

Finally, following these tips should help reduce the number of blisters below the problem stage. Call DUOMIT if you have any similar issues and need prompt assistance.