Why does Crack occur on your Concrete Floor?

Random cracking of concrete slabs is a frequent cause of complaints. As stated in the Foreword to ACI 302.1R-04, “Guide for Concrete Floor and Slab Construction,” published by the American Concrete Institute:

“Even with the best floor designs and proper construction, it is unrealistic to expect crackfree and curl-free floors. Consequently, every owner should be advised by both the designer and contractor that it is normal to expect some amount of cracking and curling on every project. And that such occurrence does not necessarily reflect adversely on either the adequacy of the floor’s design or the quality of its construction.”

Cracking can arise from various factors, such as:

- drying shrinkage

- thermal contraction

- stress (external or internal) on shortening

- subsidence of the support

- applied loads.

The applicator can moderately reduce cracking if the causes are considered and preventive measures are used. For example, sawing joints according to the drawings and installing “force cracks” in hidden places.

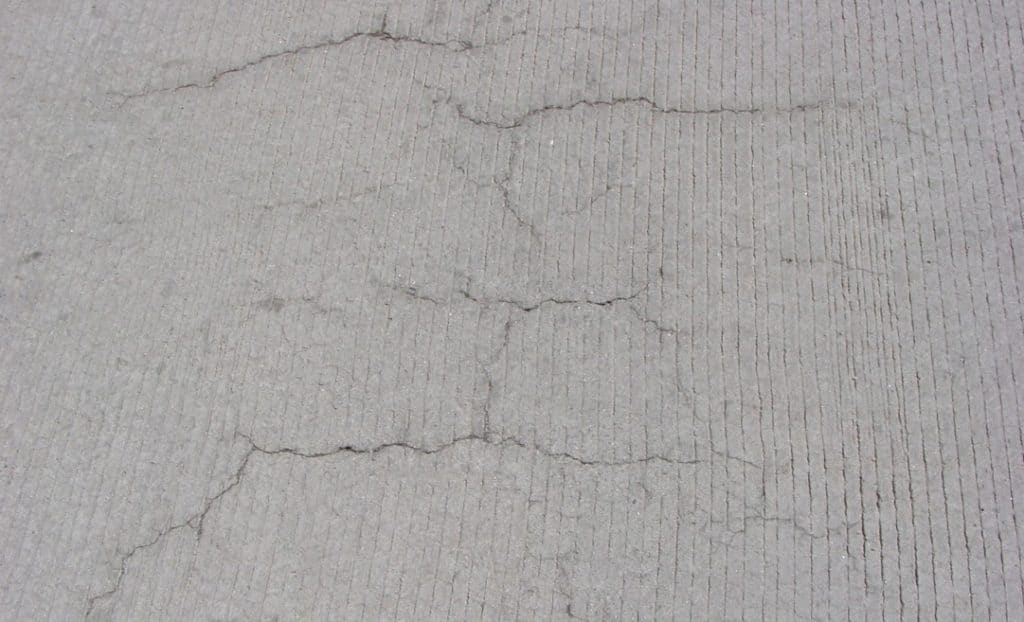

What is Plastic shrinkage?

Pre-hardening cracks generally result from “plastic” shrinkage of the surface due to rapid water loss or rapid settlement in the concrete mass. Settlement cracks can occur in embedded elements next to formwork, reinforcing steel, or hardened concrete when the concrete sinks or settles.

Settlement cracks are due to:

- too wet concrete (significant settlements),

- vibrations (insufficient consolidation),

- insufficient thickness on the incorporated elements.

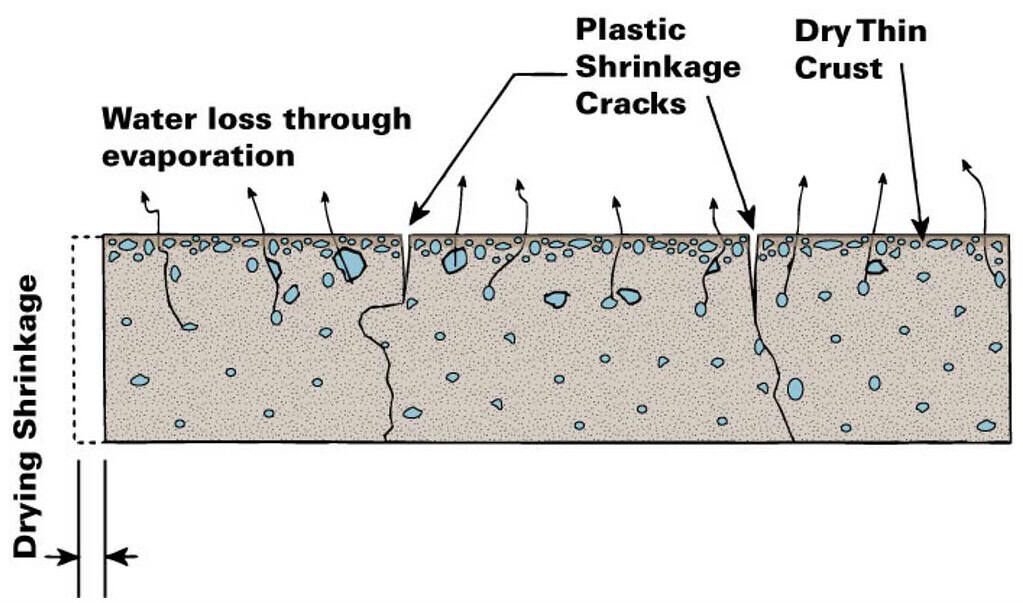

Plastic shrinkage cracks are relatively short cracks that can occur prior to finishing. Specifically, if the panel is exposed to wind, high temperatures, or low humidity. This happens as a result of the surface wetness evaporating quicker than it may be replaced by the rise in purge water. Inflicting the surface to shrink over the inside concrete.

Since the interior concrete maintains the shrinkage of the surface concrete, the stresses exceed the tensile strength of the concrete, causing the surface to crack. Under certain combinations of conditions, warped or wrinkled underscores can also occur.

Plastic shrinkage cracks vary in length, often penetrating up to half the depth of a slab. And are spaced a few inches up to 10 ft. Generally, cracks that occur after hardening result from thermal contraction, drying shrinkage, or subgrade settlement.

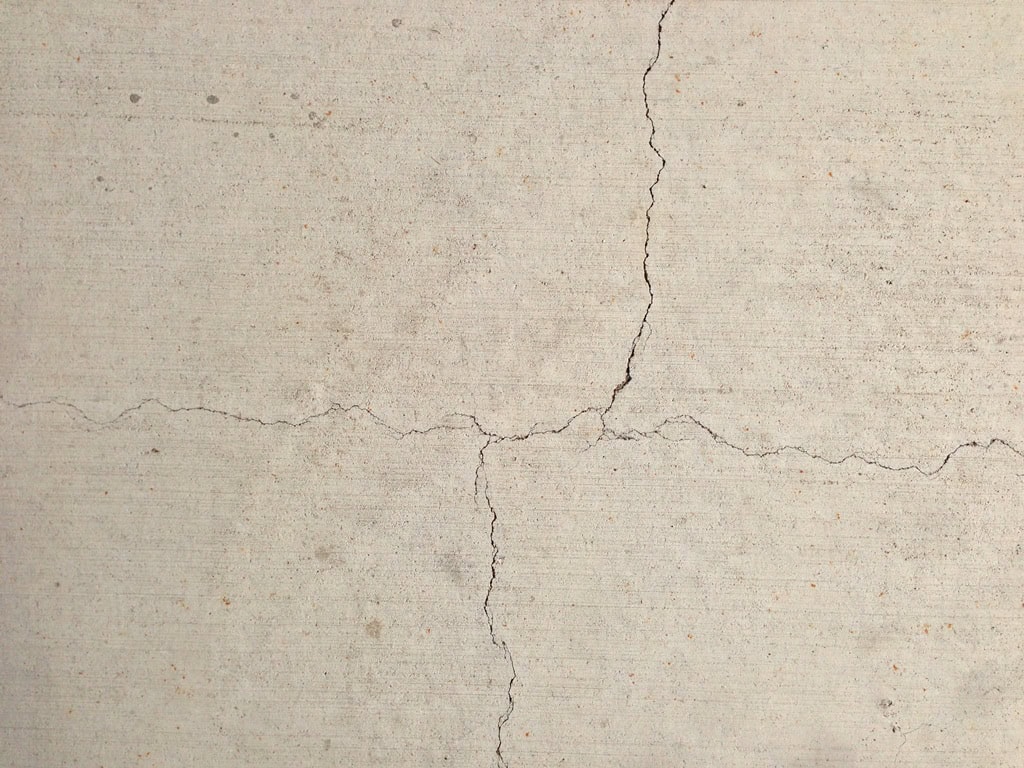

Cracking due to concrete Settling

During drying and curing, the concrete shrinks to approximately 1/16″ in 10 feet of length. Placing the joints at typical intervals will control the location of the cracks and accommodate the shrinkage. Contraction joints should be spaced at intervals of approx 10 feet in each direction in unreinforced concrete slabs 4″ thick.

The main factor affecting the drying shrinkage properties of concrete is the total water content of the concrete. The shrinkage increases proportionally with increasing water content.

Large increases in sand content and significant reductions in the size of large aggregates increase shrinkage. Because total water is increased, and smaller coarse aggregates provide less internal retention at shrinkage.

The use of mixtures of calcium chloride and high shrinkage aggregates also increases shrinkage. Mixed cement content 470 to 750 lb/yd3, or “5-8 bags” – increases in cement content have little or no effect on shrinkage if the water content is not significantly increased.

Why concrete is cracking?

Silica fumes can produce a very cohesive and tacky concrete with a low bleeding capacity. However, silica fume concrete is prone to plastic shrinkage cracking in hot, windy weather with little or no water spillage on the surface. Misting air over concrete and installing wind curtains reduces the risk of cracking due to plastic shrinkage.

Concrete features a constant of thermal growth and contraction of roughly 5.5 x 10-6 per °F. Concrete placed during warm midday temperatures will shrink as it cools overnight. A 40 ° F drop in temperature between day and night – which is not uncommon in some areas – would cause a contraction of about 0.03 inches in a 10-foot length of concrete, enough to cause cracks if the concrete is retained.

Thermal expansion can cause cracks. Insufficiently compacted sub-floors and soils sensitive to frost heaving or swelling can cause slab cracks. Overloading concrete slabs also leads to flex cracks and possible failure.

How to eliminate cracks?

Cracking in concrete can be eliminated or reduced substantially by observing the following practices:

- Substrate preparation, including a uniform substrate and suitable substrate material for an acceptable moisture content.

- Minimize the mixed water content by maximizing the size and amount of coarse aggregate and use low shrinkage aggregate.

- Use the lowest water mixture required for workability; do not allow excessively wet textures

- Avoid calcium chloride additives

- Avoid rapid loss of surface moisture while concrete is still plastic by using spray applied finishing aids or plastic sheeting to prevent shrinkage cracks plastic

- Make shrink joints 30 times the thickness of the panel at appropriate intervals.

- Provide insulation joints to avoid stress from adjacent elements of a structure.

- Prevent extreme temperature changes.

- To minimize cracking on top of vapor barriers, use a 4 inch layer of slightly damp, compactable and draining backfill, buffered with fine grade material. If concrete is to be laid directly over polyethylene sheet or other vapor barriers, laid directly over polyethylene sheet or other vapor barriers, use a low water mix.

- Correctly position, consolidate, finish and harden the concrete.

- Avoid using excessive amounts of cementitious materials.

- Consider using a shrinkage reducing additive to reduce drying shrinkage, which can minimize shrinkage cracking.

- Consider using polymer fibers to support the control of shrinkage cracks.

Conclusion

Cracks can also arise from the cooling and thawing of saturated concrete, the reactivity of alkaline aggregates, sulfate attack, or corrosion of reinforcing steel. However, cracks from these sources cannot appear for years.

Concrete materials will considerably scale back or eliminate the formation of cracks and deterioration related to phase transition and thawing, the reactivity of alkalic aggregates, salt attack, or steel corrosion.

You can also read about crack repairs on your concrete floor or why concrete is blistering? If you have a damaged or cracked driveway slab, you might be interested to see how to resurface your outdoor slab.