Epoxy Resin: Different types of resins

There are so many uses for synthetic resin; it can be shaped and molded into any structure or shape, it can be used as an epoxy, and it can be camouflaged and mixed as the substance it adheres to works with. In this post, we give you an overview of the different types of epoxy resin.

What is Epoxy Resin?

To begin with, several types of synthetic resin are available on the market, each with its own properties and composition. Here you will find out the following types of resins: Epoxy Resin, Polyurethane, and Polyester. Also, most resins are made up of two components: the base resin and the hardener (catalyst).

Importantly, when you start mixing these components, you start a chemical reaction that allows the resin to dry. This is a versatile form of resin with many uses, making it the go-to resin for many projects.

Epoxy Resin Pros

Firm and durable

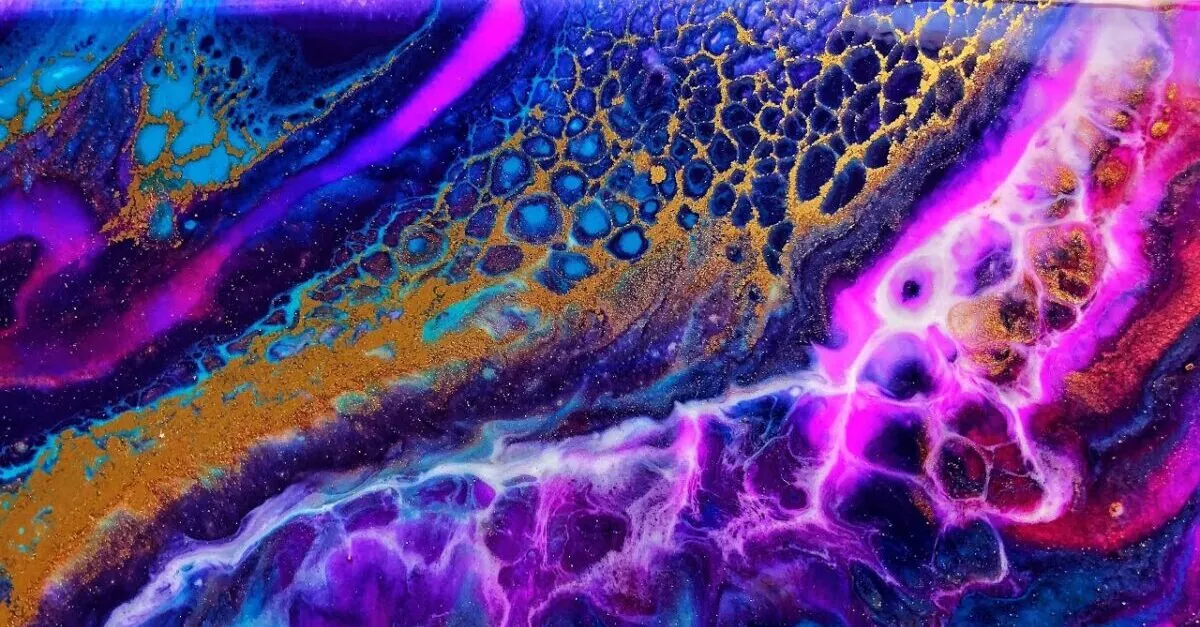

Extremely easy to customize and design

Long-lasting materials, when applied properly

Quite inexpensive, types vary and availability.

Epoxy resin can be utilized for the largest number of installations.

Epoxy Resin Cons

Yellowing when exposed to direct sunlight

Requires a dry atmosphere to set up sufficiently

Not recommended for use in high humidity environments

Application

Firstly, applies the resin layer by layer, allowing each layer to dry before laying down the next layer.

Secondly, you can sand down the resin once you have applied the prime coat.

Lastly, further sanding is necessary only in case of outgassing.

Polyurethane Resin

As a matter of fact, you can use polyurethane resin for casting molds, and it is a strong product that can be installed to make a variety of items. Moreover, polyurethane resin is very durable and, when set through applying heat, becomes very hard. Various polyurethane resins are used in several different industries, such as many appliances with polyurethane products. Polyurethane is also often found used in the automotive industry.

Polyurethane Resin Pros

Highly resistant to UV light

Resistant to the high-temperature environment after installation

Dries very quickly

It has amazing flow properties and easy to mix

It makes it easy to cover a mold

No shrinkage during the setting process.

Polyurethane Resin Cons

It has worse adhesion than epoxy resin.

Highly sensitive to moisture, this can cause foaming

Unpleasant odor while curing process

No odor, once the resin has cured

Additional additive required for low-temperature applications

Polyurethane Application

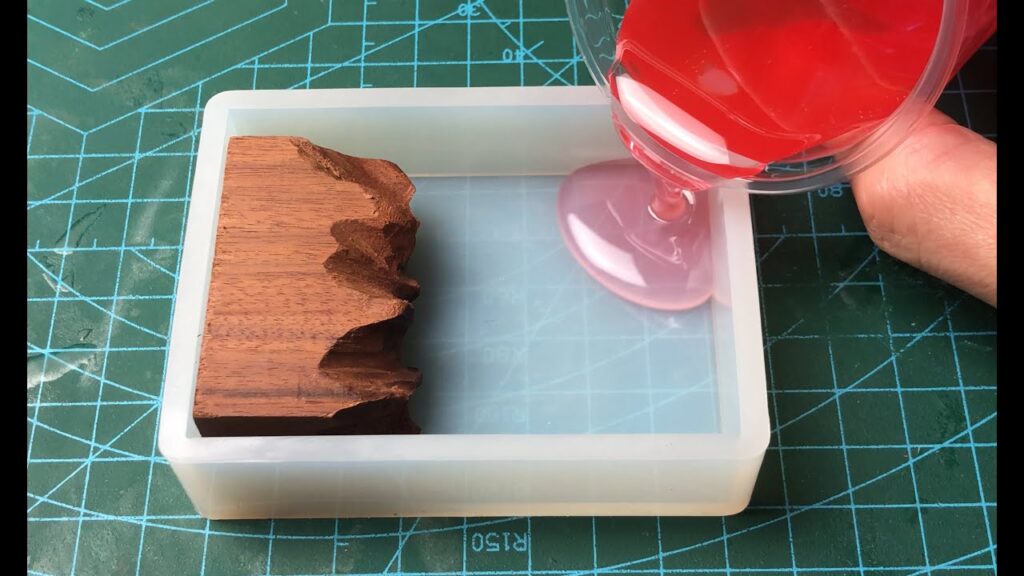

Firstly, if you are doing a mold casting with PU resin you will need to mix the two components before you pour the resin into the mold.

Secondly, polyurethane topcoat application will guaranty high strength and make the surface slip-resistant.

Polyester Resin vs Epoxy resin

Lastly, similar to epoxy resin, polyester resin can be used to make models. It is most often used in swimming pools, make ponds, and in the manufacturing of boats. Furthermore, the resin produces a strong composite material with a fiber structure that is water-resistant.

Polyester Resin Pros

Firstly, the percentage of hardeners is variable and determines the curing time based on temperature.

Also, it’s highly durable and resistant to UV light and water

Very affordable pricing

Lastly, flexible drying time is required, as the setting time is connected to the amount of catalyst.

Polyester Resin Cons

In fact, the mixing process is more challenging and actually quite technical.

You have to calculate the required amounts when mixing the two components.

Furthermore, it has a high odor and produces a strong unpleasant smell.

Polyester Application

Firstly, mixing is the same as with other resins – mix A and B.

Secondly, you have to calculate the amount of hardener that is added depending on the temperature of the application.

Finally, make sure you apply the coats in different directions. Also, this will help to avoid roller marks.

Conclusion

Finally, a different type of resin you can use is completely tied to the project you have chosen to tackle. As we described in this article, each resin has its own pros and cons. One of the biggest positive details of synthetic resins is that they can be mixed and installed as the substance they adhered to.

We hope you will find this info useful for your exciting projects. If you require a professional installer, DUOMIT is here to help. Please request a Free Estimate from your Concrete Contractors Near Me. Read also about Quartz Flooring Installations and Epoxy Basement Floor.