Dur-A-Flex Flooring – Upscale Seamless Floors

Dur-A-Flex Flooring – Durable, Extremely hygienic, and Attractive, Seamless floors are preferred for food industries. Resinous floors are applied to concrete, and most systems require a primer for proper bonding. A base coat is installed for strength and thickness, followed by a broadcast or grout coat which gives aesthetics and textures. The last – a performance topcoat is applied to protect against normal wear and tear, chemical attack, and cleaning.

HYBRID Dur-A-Flex Flooring

Dur-A-Flex’s industrial hybrid flooring is a solid-color, decorative quartz or chip floor system that is self-priming, self-leveling, and highly resistant to moisture and impact.

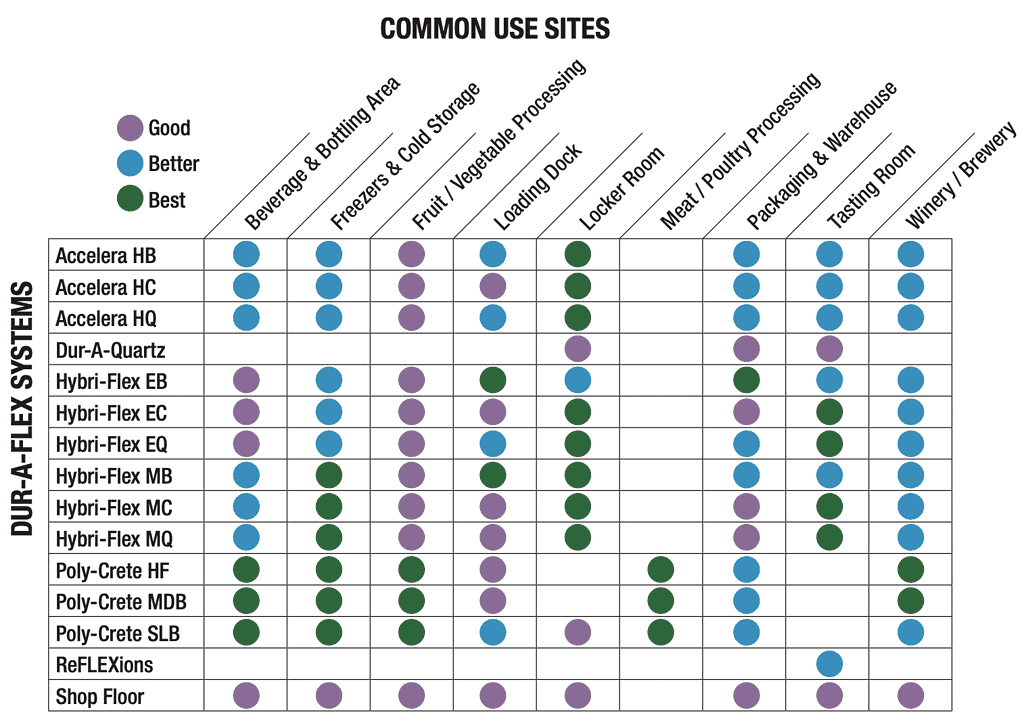

- Hybri-Flex EQ systems offer – high moisture tolerance and thicker, self-priming, self-leveling flooring. It is a great choice for installation on rough existing floors, freshly placed concrete, or where higher impact resistance is desired. Hybri-Flex EQ is a decorative, colored-quartz hybrid floor system consisting of a urethane base coat with epoxy and urethane topcoats. Quartz is available in fine (Q28) and coarse (Q11) sizes.

- Hybri-Flex MC is a decorative chip, hybrid floor system consisting of a urethane cement base coat and one-hour-curing methyl methacrylate (MMA) topcoats. Installation in just two days greatly reduces interruptions to business. Decorative chips are available in both micro and macro sizes.

Poly-Crete Urethane Flooring

Dur-A-Flex cementitious urethane flooring is highly resistant to chemicals and formulated to install quickly and consistently with an excellent wear surface and color stability.

- Poly-Crete SLB is a seamless, 3/16″, 100% solids, self-priming cementitious-urethane, self-leveling, concrete resurfacing system with a natural quartz aggregate broadcast providing a slip-resistant, gloss finish. The combination of two-part urethane technology, portland cement, and select aggregates provides attributes similar to concrete, making it very resistant to thermal shock.

- Poly-Crete MDB is a seamless, ¼-inch, 100% solids, aromatic, self-priming cementitious urethane concrete coating system with a natural quartz aggregate broadcast provides a slip-resistant, gloss finish. Its coefficient of thermal expansion is similar to concrete, making it very resistant to thermal shock. Highly resistant to chemicals and food acids. Use with Poly-Crete TF Plus topcoat for UV resistance that ensures color stability. Integrate into a Dur-A-Flex cove system for a completely seamless floor.

- Poly-Crete Dur-A-Flex Brochure and Poly-Crete Color Chart

- Poly-Crete SLB Brochure and Poly-Crete MDB Brochure

Shop Floor Epoxy

Dur-A-Flex’s commercial epoxy floor systems feature high-performance stain, chemical and wear resistance in solid color, and decorative options for a modest investment.

- Shop Floor – is a solid color 1/16 – ¼” seamless flooring system consisting of 100% solids epoxy and natural quartz aggregates with a chemical and wear-resistant urethane topcoat. Easy to maintain and durable, it is ideal for industrial flooring applications.

- Shop Floor MR is a non-slip solid color 1/16 – 1/8” seamless pigmented flooring system consisting of 100% solids epoxy and natural quartz aggregates with a chemical and wear-resistant urethane topcoat. Designed for use in heavy-duty/heavy traffic mechanical or server rooms, Shop Floor MR consists of an optional primer/moisture barrier for use over green concrete, an elastomeric waterproofing membrane, broadcast coats, and a recommended topcoat for added abrasion and UV resistance.

- Shop Floor Dur-A-Flex MR Brochure and Shop Floor Dur-A-Flex Brochure

- Epoxy Dur-A-Flex Brochure and Dur-A-Quartz Brochure

- Chemical Resistance Chart Dur-A-Flex